|

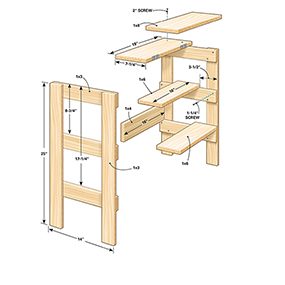

| Plans for the Ridiculously Simple Shop Stool from The Family Handyman |

Some important characteristics is that it is built from 1X dimensional lumber (so the wood is cheap) and it is all short straight cuts, which is important because I do not have a mitre saw, a table saw, or a router.

|

| My backyard workshop |

|

| Cut wood for two shop stools |

|

| Cutting boards with a Compact Circular Saw and a Carpenters square. |

Next step was sanding the boards and staining them. I used a rasp to break the corners, then three rounds with sand paper. Staining was with Dutch Oil.

|

| Staining boards |

For assembly the hard part was the fact that 1X dimensional lumber is prone to splitting. I split my first two, then I noted that the instructions say to pre-drill holes to prevent splitting. After that it was a lot easier.

The next tricky part was getting the steps in. The side slabs make it hard to get access to the tops of the steps. I think pocket screws would work, if I was up to learning how to do pocket screws. Another new purchase was a right-angle driver/drill head for my Rigdig Jobmax multi-tool. The advantage is that I can drive in wood screws without as much space as the average cordless screwdriver.

After getting all the supports and steps glued, pre-drilled, and screwed in, we had the structure of the shop stool.

|

| Complete shop stool |

Next was to put finishing touches on it. Scrapped off the excess glue. Added non-stick safety tape on the steps. Added hinges so that the second half of the top can be opened to make a stool top or folded to allow for steps. Added felt pads on the feet and on the top to protect the floor and to soften the sound when the top is opened or closed.

|

| Two completed shop stools in the kitchen |

A nice little project. It turns out to require use of two new tools (the Rockwell compact circular saw and the Rigdig Jobmax Right Angle driver). It will get multiple uses, as stools my in-laws like to eat at the kitchen counter when they are at our place so they can use two stools. The steps are tall enough that my 4-yr old son can now help food prep and operate the microwave. The stool tops are good for side tables in our living room (so we can sit at our couches and eat). They also make for good work surfaces in the kitchen (that will always be clear because we need to use them for other reasons).

Very nice project. Thanks to The Family Handyman for providing the plans.

1 comment:

The Warning yellow tape in India is a reliable and durable safety solution for marking off restricted or hazardous areas. I’ve used the Barricade Tape multiple times for construction and event setups, and it holds up well in all weather conditions. The bright color and bold lettering make it highly visible from a distance, ensuring clear communication of boundaries. Overall, the Barricade Tape is an essential tool for anyone needing quick, effective safety marking. Highly recommended for both professionals and DIY use!

Post a Comment